|

|

|

| Indentor |

|

Height: 2.54mm Shape: Cylindrical |

|

|

| Pressure foot |

|

A 50mm diameter pressure foot in contact with a specimen, is wide enough to offer stable measurement. |

|

|

| Hardness Tester Selection Chart |

|

|

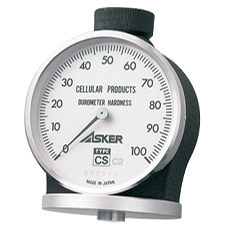

Our product line consists of various types of durometers applicable to specific materials

as indicated in the chart above.

Type A Durometer (ASKER A type), conforming to JIS K 6235 is the most popular type of durometer for measuring rubber hardness.

However, verification is recommended because a significant difference is estimated to be the largest when a durometer indicates measurement values from 10 to 90 points.

For hard specimens for which Type A Durometer readings indicate more than 90 points, measurements should be undertaken using the Type D Durometer (ASKER D type). However, for soft specimens with measurements of less than 20 points, the ASKER C type or Type E Durometer (ASKER E type) should be used. The most important consideration in using durometers is to select the correct type for purposes of measurement according to the specimen.

|

|

|

Specification |

|

|

|

| Indication range |

|

0 point - 100 point (262 degree dial scale) |

|

|

| Minimum indication |

|

1 point (Accuracy : ±1 point) |

|

|

| Indentor Design (mm) |

|

Height: 2.54 10 Dia. Cylindrical |

|

|

| Spring Forces [mN(g)] |

|

|

|

|

| Central hole of diameter of Pressure foot |

|

Φ10.5 |

|

|

Pressure foot

Dimension (mm) |

|

Φ50(Round shape) |

|

|

| Outer Dimension (mm) |

|

Approx. Width 50×Depth 50×Height 76 |

|

|

| Weight (g) |

|

250 |

|

|

| Application |

|

Polystyrene foam |

|

|

|

|

Option |

|

|

|

|

|

Two-pointer type (max-hand and active hand) of Rubber Hardness Tester

The stationary set hand (max-hand) makes the maximum value easier to read and allows the creep characteristics of a specimen.

Accurate measurement is made possible for specimens* for which stress relaxation occurs over time or for specimens for which it is difficult to take readings from the front.

*Materials for which the reading decreases immediately after the indentor has been pressed against the surface. |

|

|

|

|

|

Indentor Extension Tester

| · |

The gauge to check the indentor height on a durometer and the reading indicator mechanism. |

| · |

Inspection is conducted at 2, 50, and 100 points respectively. |

|

|

|